Crack repair (floor)

Key Facts

Cracks in concrete floors or screeds are as a rule subjected to changing mechanical loads. To adhesively seal the crack, epoxy resins are particularly suitable. ASODUR-K900 is probably the most practical way to simply, quickly and cleanly close cracks in screeds and concrete. We supply the low viscosity epoxy resin based product in a practical squeezy bag – including gloves, screed clips and PE pipe. You have the possibility to mix a heavy duty pourable resin as a closed system by simply squeezing.

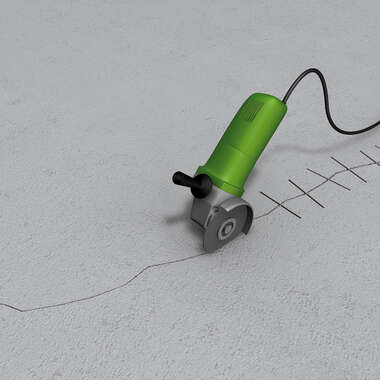

1 Opening the cracks

Saw cut the crack or joint lengthways (to approx. half to two thirds to screed depth). At right angles to the crack and at 30 cm intervals cut in10 cm long transverse slots.

2 Cleaning

Remove dust and contamination and thoroughly clean the cut area with an industrial vacuum or similar.

3 Mixing

Mix components A and B together and shake for a minimum of 15 seconds.

4 Place the screed clips

Now lay the screed clips provided into the slots.

5 Grouting the cracks

Pour the mixed material, ASODUR-GH-S into the prepared cut without leaving voids. Strike off excess material.

6 Quartz sand

Once the gel phase has been reached, broadcast with quartz sand (grain size 0.1 to 0.6 mm).

7 Vacuuming off

Once hardened, remove loose sand by vacuum.

8 Alternative

With narrow cracks up to a width of 0.4 mm, use the fluid epoxy resin, ASODUR-K900.